“First Light” is what happens when you first get a new laser to start lasing. It takes a tremendous amount of up front design:

The pump lasers need to be temperature tuned to produce the right wavelength.

The laser cavity needs to be designed to be stable, which involves quite a bit of matrix math.

The pump lasers need to be properly focused into the crystal. The focus spot size needs to closely match the Gaussian mode of the cavity.

The cavity mirrors need to be aligned perfectly.

The pump laser spot needs to closely overlap the beam inside the cavity.

Cavity Alignment

You align a laser cavity using another laser, shining the laser light through the cavity and off the mirrors, until the beam bounces back to itself. When it’s perfect, the alignment laser will start to flicker and shimmer — the reflection of the laser beam is causing interference with the laser itself. This should be a pretty easy process. It would be, except for the laser crystal.

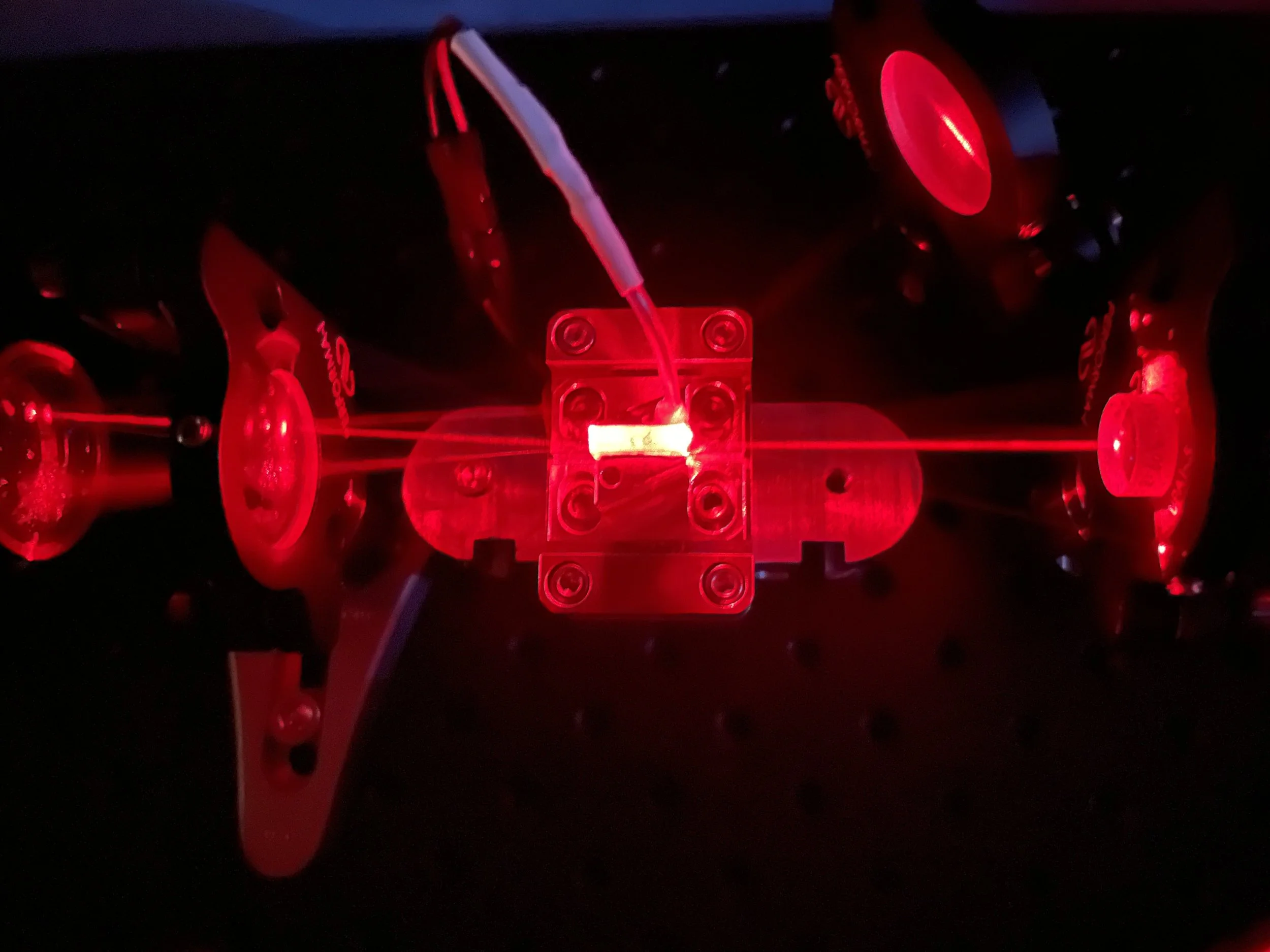

The laser crystal causes some splitting and refraction of the alignment laser. Here is an example:

Crystal refracting the pump laser

In this image a red alignment laser is coming in from the right. When it passes through the crystal the beam is deflected. If you look closely the beam is actually split into multiple beams. This makes it kind of tricky to get the mirrors aligned — what spot do you align to? To make matters worse, the deflection angle of the beam by the crystal changes with wavelength. So even if the spots are perfectly lined up the resonator will not be aligned for the wavelength of the laser.

There is an easy solution to this though. The crystal only splits the beam in one dimension. By rotating the crystal so it splits the beam on the X-axis, you can completely dial in the Y-axis. Then, align to one of the edge-most spots from the crystal and sweep the mirror’s X-axis through the rest of the spots until the laser starts working.

When it starts lasing you will be rewarded with a little laser dot on an infrared detector:

That little white dot is a laser beam.

It doesn’t look like much, but that little white dot is about two watts of laser light — enough to start things on fire. It seems so simple until you zoom out to see the rest of the apparatus needed to make it work:

Wow that’s a lot of junk.

The cavity I have working here is an “L-fold”. It only allows one pump laser. in future posts I will upgrade this design to a Z-fold and we will discover that aligning five mirrors is a lot harder than three.

Secondary Harmonic Generation (SHG)

An infrared laser is not my end goal. It is great if I wanted to cut things with it, but I think infrared beams are more dangerous because you can’t see them, and let’s face it: a bright visible beam is much more fun. How do you get a visible beam from an infrared laser? Physics! Welcome to the world of non-linear optics. Here, two infrared photons with a wavelength of 1064nm enter a non-linear crystal and combine into a single photon at half the wavelength of 532nm: a nice bright green. There are many papers and books that describe in great detail how this works. Those books are a great resource if you’re trying to discover new non-linear crystals. Lucky for me, this was solved many years ago and now there are many good choices. The crystal I’m using is KTP, which is pretty efficient and reasonably easy to use. You just have to keep the crystal oriented at just the right angle, regulate its temperature to within about a tenth of a degree Celsius, and keep an energy density of tens of thousands of watts / cm^2.

While KTP can be pretty efficient at converting infrared to green, it only is only efficient when given very intense laser light. It’s not enough to just shine the laser through it; the energy density won’t be nearly high enough. You can Q-switch the infrared laser, which can amplify the peak laser power by several orders of magnitude, or you can put the KTP crystal inside the laser cavity itself. The intracavity energy density is much higher than the output beam.

While I do want to experiment with Q-switching, I feel like I should learn to walk before I run. Q-swtiching it significantly more stressful to the laser resonator. The resonator has to be designed for it and mistakes generally result in damaged optics. Instead, I will put the KTP crystal inside the laser cavity.

There is an advantage of intracavity fequency doubling I really like. A laser’s output is only a small percentage of the power inside the cavity. According to my math the optimum percentage for my laser cavity is about 7%. If I remove the partially transparent mirror and replace it with a mirror that is 100% reflective to infrared but 100% transparent to green, I only need 7% green conversion efficiency to have full power output. Compare this to frequency doubling a Q-switched laser outside the cavity: efficiency here can be 80% if you are very careful. But that means you’re still losing 20% of the power (or worse, passing it along as dangerous infrared in the beam).

To test my KTP, I inserted it into the resonator. I kept the existing 80% reflective output coupler — it’s my “safety valve”. Should green conversion not work two 100% reflective mirrors can build up damaging power levels inside the laser resonator. Keeping the 80% mirror in place allows me to safely experiment. And…green:

Pretty green beam

It’s dim, but it worked on the first try. Of course I didn’t know this because I was wearing goggles that filter green, but I make heavy use of my cell phone camera when looking at things I can’t see with goggles on. This green dot is a mix of both green and infrared.

I did try a pure green beam. That was a costly mistake. At some point I lost green conversion and built up energy in the resonator and cracked my laser crystal. It likely suffered something called “self focusing” where it forms a thermal lens and focuses the laser energy into itself.

Next up: new crystal, new crystal mount and a Z-fold cavity.